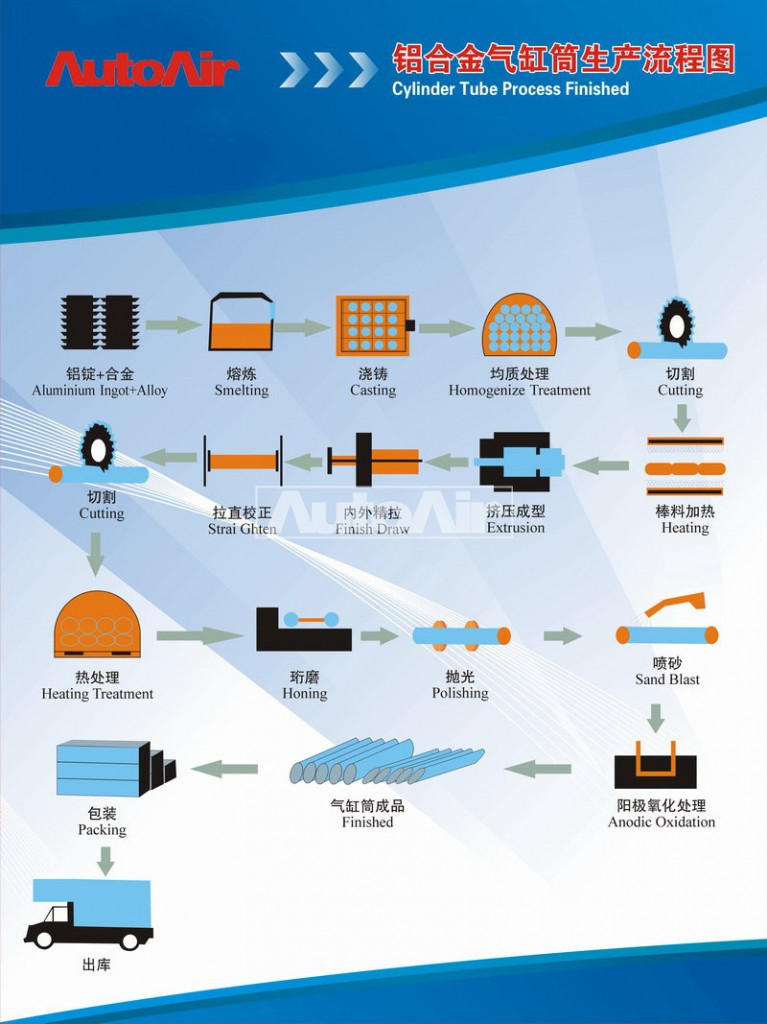

Ts'ebetso ea Tlhahiso ea Pneumatic Cylinder Tube

Raw Material workshop

Raw Material workshop

Extrusion Workshop

Extrusion Workshop

Qetella Draw workshop

Qetella Draw workshop

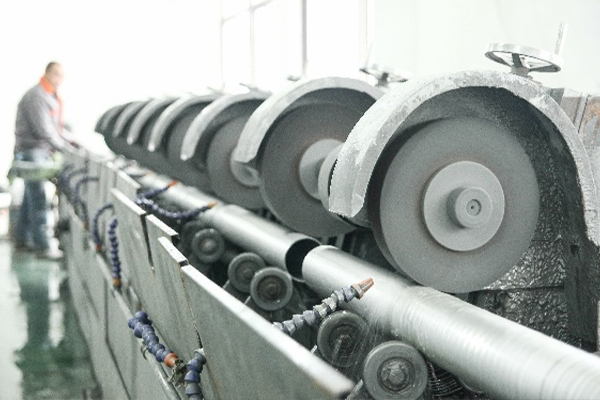

Honing Workshop

Honing Workshop

Mosebetsi oa ho pola

Mosebetsi oa ho pola

Lehlabathe Blast Workshop

Lehlabathe Blast Workshop

Anodic Oxidation Workshop

Anodic Oxidation Workshop

Ho paka Pneumatic cylinder Tube

Ho paka Pneumatic cylinder Tube

Itokiselitse thepa workshop

Itokiselitse thepa workshop

Pele ho tsohle, ka mor'a ho amohela litšoantšo tse entsoeng ke moreki kapa moreki a nka litšoantšo tsa rona tse tloaelehileng, re tla reka thepa e tala bakeng sa ho bula hlobo.

Mohato oa 1:Profil ea Aluminium e ekelitsoeng ho latela setšoantšo ka hlobo

Lisete tse 2 tsa mochini o boima oa aluminium profil ea extrusion

Mohato oa 2:Qetella ho taka

Mohato oa 3:Otlolla

Mohato 4:Ho poma

Mohato oa 5:Kalafo ea ho futhumatsa

Mohato oa 6:Honing

Li-sete tse 12 tsa metjhini e holisang ea Pneumatic cylinder tube honing

LBH:

Q1: Honing ke eng?

A: Ho qeta ts'ebetso ea sebaka sa ho qetela ka whetstone (eo hape e bitsoang honing stick) e kentsoeng hloohong ea honing.E boetse e tsejoa e le boring.Haholo-holo e sebetsana le likoti tse fapaneng tsa cylindrical tse bophara ba 5 ho 500 mm kapa tse kholoanyane, 'me karo-karolelano ea botebo ba sekoti ho bophara ba lesoba e ka fihla ho 10 kapa ho feta.Tlas'a maemo a itseng, e ka boela ea sebetsana le lifofane, libaka tse chitja tse ka ntle, libaka tse chitja, libaka tsa meno, joalo-joalo. Selikalikoe se ka ntle sa hlooho ea honing se khabisitsoe ka li-whetstones tse 2-10 tse bolelele ba hoo e ka bang 1/3 ho isa ho 3/4 ea bolelele ba lesoba.Ha e leotsa lesoba, e potoloha ebe e ea pele le morao.Ka nako e ts'oanang, e atoloha ka ho lekana ka nako ea selemo kapa taolo ea haeteroliki hloohong ea honing.Ka hona, sebaka sa ho kopana le holim'a sekoti se seholoanyane, 'me katleho ea ho sebetsa e phahame.Ho nepahala ha sekoti ka mor'a ho honoa ke IT7 ~ 4, 'me ho khopama ho ka fihla ho Ra0.32 ~ 0.04 microns.Boholo ba tumello ea honing bo itšetlehile ka bophara ba lesoba le thepa ea workpiece, ka kakaretso 0.02 ~ 0.15 mm bakeng sa likarolo tsa tšepe tse entsoeng ka tšepe le 0.01 ~ 0.05 mm bakeng sa likarolo tsa tšepe.Lebelo le potolohang la hlooho ea honing hangata ke 100 ~ 200 rpm, 'me lebelo la motsamao o phetoang hangata ke 15 ~ 20 m/min.E le ho tlosa li-chips tsa ho itšeha le likaroloana tsa abrasive, ho ntlafatsa ho hlaba holimo le ho fokotsa mocheso oa sebaka sa ho itšeha, hangata ho sebelisoa mokelikeli o mongata, joalo ka parafine kapa oli e nyenyane ea spindle nakong ea ts'ebetso. ka linako tse ling emulsion ea khatello e feteletseng e boetse e sebelisoa.

Mohato oa 7:Ho benya

Li-sete tse 2 tsa mochini o benyang holim'a metsi

Mohato 8:Ho phatloha ha lehlabathe

Li-sete tse 2 tsa mechini ea ho qhomisa lehlabathe

LBH

Q1: Ho phatloha ha lehlabathe ke eng?

A: Mokhoa oa ho sebelisa tšusumetso ea phallo ea lehlabathe le lebelo le phahameng ho hloekisa le ho hlaba bokaholimo ba substrate.Moea o hatelitsoeng o sebelisoa e le matla a ho etsa sefate sa jete se lebelo le phahameng ho fafatsa thepa ea ho fafatsa (ore ea koporo, lehlabathe la quartz, lehlabathe la emery, lehlabathe la tšepe, lehlabathe la Hainan) ka lebelo le phahameng ho ea holim'a mochini oa mosebetsi o lokelang ho phekoloa, ponahalo kapa sebopeho sa bokaholimo ba bokaholimo ba sebaka sa mosebetsi se fetotsoe , Ka lebaka la ts'usumetso le ketso ea ho itšeha ea abrasive holim'a sebaka sa mosebetsi, bokaholimo ba mosebetsi bo ka fumana tekanyo e itseng ea bohloeki le bohloeki bo fapaneng, thepa ea mechine ea holim'a workpiece e ntlafatsoa, kahoo ho ntlafatsa ho hanyetsa mokhathala oa workpiece, le ho eketsa eona le ho roala Ho khomarela pakeng tsa lihlopha ho atolosa ho tšoarella ha filimi ea ho roala, hape ho loketse ho leka-lekanya le mokhabiso oa ho roala.

Mohato oa 9:Anodizing

Li-sete tse 2 tsa mela ea kalafo ea anodizing

LBH:

Q1: Anodizing ke eng?

A: Anodic oxidation, electrochemical oxidation ea tšepe kapa alloys.Aluminium le metsoako ea eona e theha lera la filimi ea oxide lihlahisoa tsa aluminium (anode) tlas'a ts'ebetso ea hona joale e sebelisoang tlas'a electrolyte e lumellanang le maemo a itseng a tshebetso.Haeba anodizing e sa hlalosoa, hangata e bua ka anodizing ea sulfuric acid.

Bakeng sa ho hlola bofokoli ba ho thatafala ha aluminium alloy holim'a metsi, ho hanyetsa ho roala le likarolo tse ling, ho holisa sebaka sa ts'ebeliso, le ho lelefatsa bophelo ba ts'ebeletso, theknoloji ea kalafo ea holim'a metsi e fetohile karolo ea bohlokoa ea ts'ebeliso ea motsoako oa aluminium, mme theknoloji ea anodizing e se e le teng hona joale. e sebelisoang haholo le e atlehileng ka ho fetisisa ea.

Mohato oa 10:Li-tubes tse phethiloeng tsa aluminium cylinder

Mohato oa 11:Aluminium cylinder tubes e paka